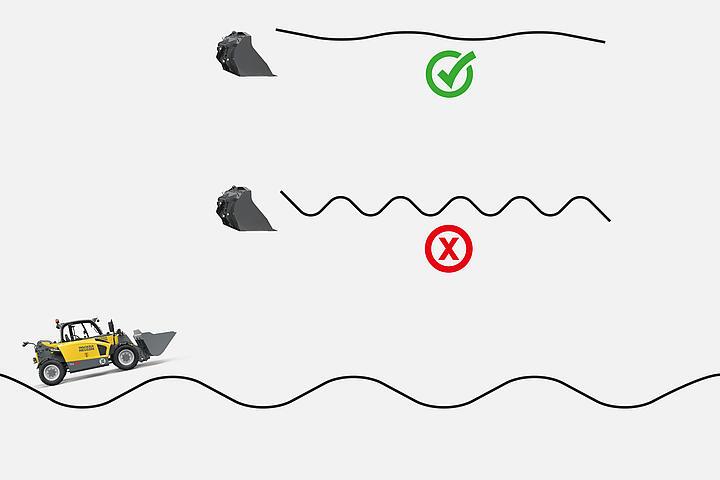

Excellent all-round visibility

- The TH522’s cab provides a good overview of the attachments, the immediate work area and the entire area around the machine. In combination with the sloping engine bonnet, the low side window on the right-hand side and the high seat position ensure an optimal view. This increases safety across the machine's entire work area.

- For an even better overview, there is also the cabin elevation option for the TH522, which raises is by 200 mm. Thanks to the wide front windscreen and roof window, it is always possible to view the attachment. This is particularly important to effectively and safely work with the telehandler at height.